Things about Motorcycle Parts New Zealand Specialists

Table of ContentsRumored Buzz on Motorcycle Parts New Zealand SpecialistsRumored Buzz on Motorcycle Parts New Zealand SpecialistsUnknown Facts About Motorcycle Parts New Zealand SpecialistsMore About Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists - QuestionsNot known Details About Motorcycle Parts New Zealand Specialists The Ultimate Guide To Motorcycle Parts New Zealand SpecialistsFacts About Motorcycle Parts New Zealand Specialists Uncovered

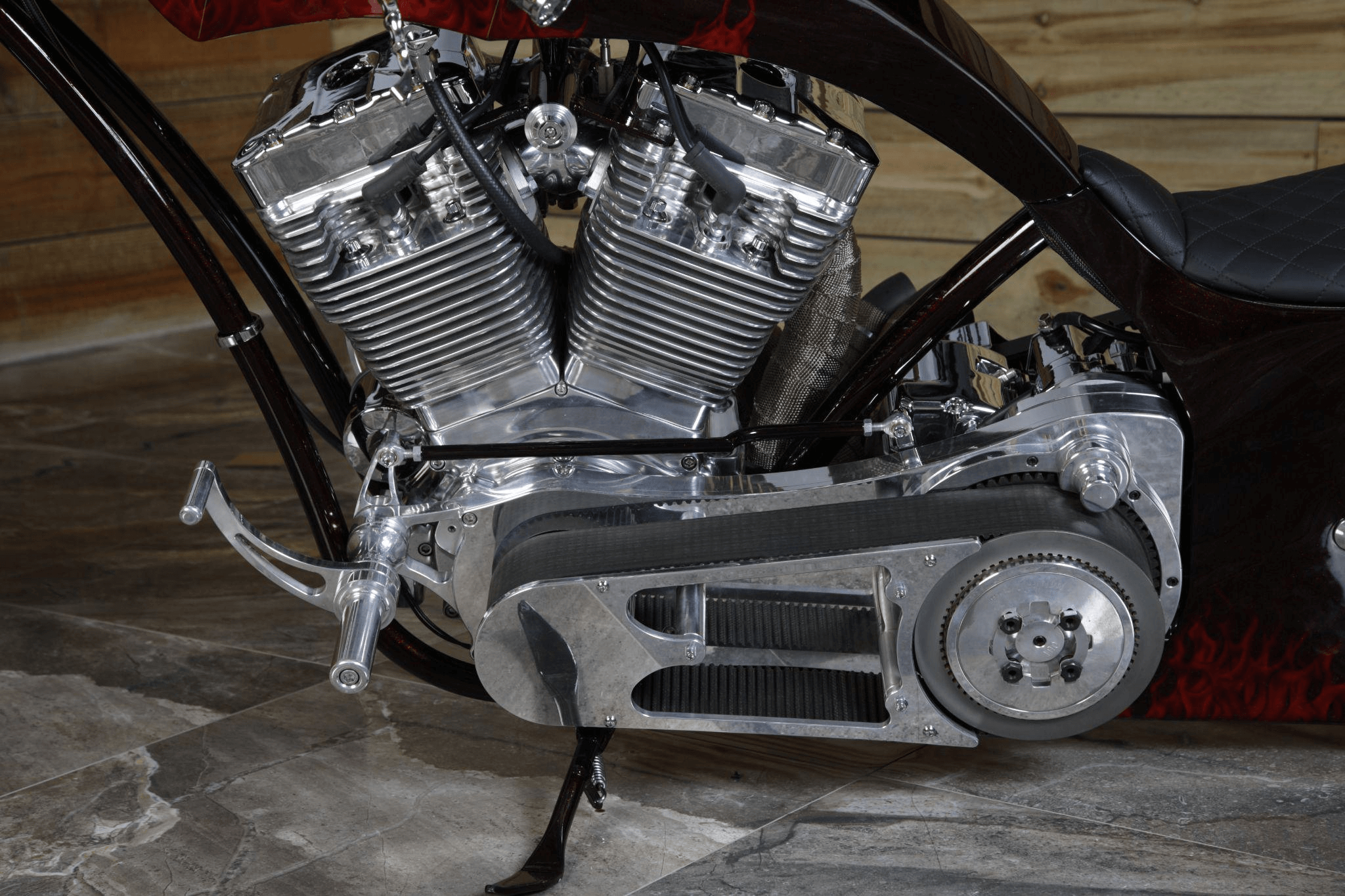

Reach out to one of our experts today.CNC machining innovation is promptly becoming the prime focus of various manufacturing processes around the globe as a direct outcome of its many advantages over various other techniques. In addition, the industries that manufacture bikes have jumped on board with this pattern. The most ingenious companies are now creating their engine components and wheels making use of machining techniques initially established for motorcycle components.

You might be questioning why we make use of. Currently that we have your attention allow us clarify the reasoning behind this contemporary growth in the bike production sector.

The 7-Second Trick For Motorcycle Parts New Zealand Specialists

In enhancement, you have complete control over the appearance of the elements, also down to the min details. Periodically, motorcyclists may make a decision to spruce up their trip by setting up aftermarket components or customizing the bike's remodeling.

Motorcycle Parts New Zealand Specialists - Questions

CNC machining might be used to make nearly all of a motorcycle's steel and plastic components. To continue, we'll discuss a number of machined parts for motorbikes. In comparison to those on autos, wheels on motorcycles tend to be a lot more noticeable. Consequently, the bike's looks may be enhanced with the ideal personalization of these wheels.

Milling procedures are utilized to acquire the preferred level of wheel modification. Another aspect of the motorcycle that might be individualized is the tires.

The 9-Minute Rule for Motorcycle Parts New Zealand Specialists

When it pertains to a car (or a motorcycle), the most crucial part is the engine. Numerous individuals mention it as the "heart" of the auto. On the various other hand, the camshaft, the cyndrical tube head, and the pistons tend to be complex and require styles with a high level of accuracy.

Illumination is one more facility element of customization. Usage just high-quality items, however, given that these lights are essential for the security of motorcyclists and other drivers or individuals when driving, particularly during the night. Bike headlights have three major components: the light bulb, or light resource, the lens, and the real estate. Specifically, we customize the lens and the real estate.

Milling procedures with a flawless coating would certainly result in the lenses having a reflective quality that is similar to that of a mirror. The cover, on the other hand, is not made up of breakable products; rather, it is constructed out of difficult polymers that can be machined into even more complex patterns.

Little Known Questions About Motorcycle Parts New Zealand Specialists.

They commonly have sophisticated geometries with a riches of min information. Motorbike producers typically cast these elements, but just for the production hop over to these guys of bespoke parts. However, CNC machining is the technique of choice when generating unique pieces. Machining on five axes in today's globe is the methods whereby any style form may be realized.

The success of the procedure is contingent on the mill cutters' capacity to determine refined and difficult angles accurately. Select Runsom for your customized bike parts! We have the ability to produce complex and fashionable elements making your motorcycle matchless. The majority of are crafted from light weight aluminum or steel alloys, each of which has its uses and advantages.

Right here are a couple of instances of metals usually used in motorcycle element machining. Light weight aluminum is the key product made use of by business focusing on generating custom bike parts to develop a lot of these components. In the past, we would certainly construct our engines out of actors iron. On the other hand, aluminum is rapidly coming to be the material of choice, partially as a result of the fact that it is more lightweight.

Zinc refers to an additional metal that is extremely light in weight and has excellent machining top qualities as a result of its high mechanical toughness. This material may be formed right into practically any form and maintains its measurements well. Go Here Even mission-critical components that require a high degree of precision might gain from their usage.

The Main Principles Of Motorcycle Parts New Zealand Specialists

One more metal that sees hefty usage in the manufacturing of CNC-customized elements is magnesium. It is amongst the lightest metals that are now accessible and has excellent machinability functions and stamina proportionate with its low weight. One of the disadvantages of magnesium is that its dirt might easily ignite.

Due to the fact that of its premium machinability and weldability, stainless steel is an alloy that is especially fit for CNC processes. They have terrific corrosion resistance and a high visual charm. Their most common use in generating various motorcycle parts is fasteners, such as screws and screws. Their reduced susceptibility to oxidation and corrosion makes them ideal for this usage.

Motorcycle Parts New Zealand Specialists Things To Know Before You Buy

It appears that CNC transforming and milling this contact form are the fundamental procedures. Nevertheless, alternative strategies exist, such as exploration. Let's explore many of these machining techniques extensive. The CNC transforming method is taken into consideration a subtractive manufacturing technique. On top of that, it needs keeping bars of product, most usually plastic or metal, ready and after that turning a reducing device to eliminate sections of the product as the product is transformed.

These methods are equally crucial and generate elements with high precision and constant top quality. They are specifically: grinding, laser cutting, and exploration. The term "surface area coating" refers to post-processes after the initial machining phase. Motorcycle Parts New Zealand Specialists. The processes assist improve the general top quality of the machined bike elements. Below are the short intro, advantages and disadvantages of five surface area therapy approaches.

Motorcycle Parts New Zealand Specialists for Beginners